The advancements in robotics have paved the way for the introduction of robotics systems in various real-world settings, including industrial and manufacturing facilities. In these settings, robots have the potential to assist human workers by assembling certain parts of products with high precision, thereby improving efficiency. However, the interactions between robots and humans in such environments can still be enhanced. To address this, researchers at Nanjing University of Aeronautics and Astronautics in China have developed a digital twin system that aims to optimize collaboration between human and robotic agents in manufacturing settings.

The digital twin system introduced by the researchers creates a virtual map of real-world environments to plan and execute suitable robot behaviors as they work with human agents on specific tasks. Unlike current methods that rely on motion capture devices, which can be cumbersome and limit flexibility, this system provides a more intuitive and convenient approach. By modeling humans and robots in a unified space, it allows for better perception and understanding of the overall environment, leading to improved collaboration.

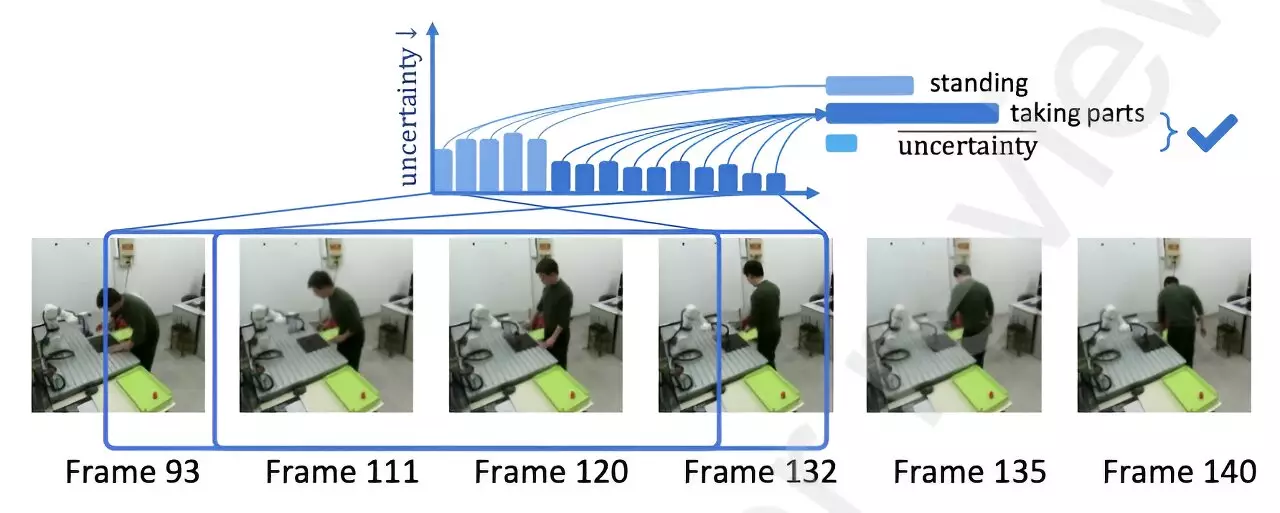

Previous digital twin systems that relied on motion capture sensors faced challenges when there were occlusions, such as objects or agents of interest being outside the sensors’ field of view or hidden behind obstacles. To overcome this, the researchers developed a human mesh recovery algorithm. This computational technique helps reconstruct occluded human bodies, enabling more accurate and comprehensive data capture. Additionally, an uncertainty estimation technique was introduced to enhance the performance of the action recognition algorithm, reducing the risk of errors.

The researchers conducted a series of experiments in laboratory settings to evaluate the effectiveness of their digital twin system. They used a robot specifically designed for industrial use and tested various tasks, including polishing, picking up, assembling, and placing down objects. The results showcased significant improvements in collaboration between the robot and human agent compared to baseline methods. The feasibility and effectiveness of the system were further validated through a case study involving component assembly.

The digital twin system developed by the researchers has promising potential for implementation in real-world settings to enhance collaboration between robots and humans in manufacturing and industrial tasks. With further testing and refinement, it could be deployed on other robots for industrial use, opening doors to a range of applications. The system’s ability to create a virtual replica of the scene and plan effective collaborative strategies will revolutionize the efficiency and productivity of human-robot collaborations.

The digital twin system introduced by the researchers at Nanjing University of Aeronautics and Astronautics offers an innovative and advanced solution to improve collaboration between robots and humans in manufacturing settings. By creating a virtual map of real-world environments and leveraging computational techniques, occlusions and uncertainties are effectively addressed. The system’s effectiveness was demonstrated through experiments, showcasing its superiority over existing methods. As this technology continues to evolve, it holds immense potential for optimizing human-robot collaborations in various industrial and manufacturing tasks.

Leave a Reply