Hydrogen fuel cells have emerged as a novel solution to address environmental challenges by providing a cleaner and more sustainable energy source. These fuel cells utilize a polymer electrolyte membrane that separates the electrodes and enables the flow of electricity. However, the inconsistent operation of fuel cells during acceleration and deceleration has led to the formation of cracks in the membrane, resulting in operational failures. While various methods have been employed to address this issue, none have been successful in completely preventing crack formation. In a recent study published in the journal Advanced Materials, researchers have developed a fatigue-resistant electrolyte membrane that shows promise in enhancing the durability and lifespan of fuel cells.

The Development of Fatigue-Resistant Electrolyte Membranes

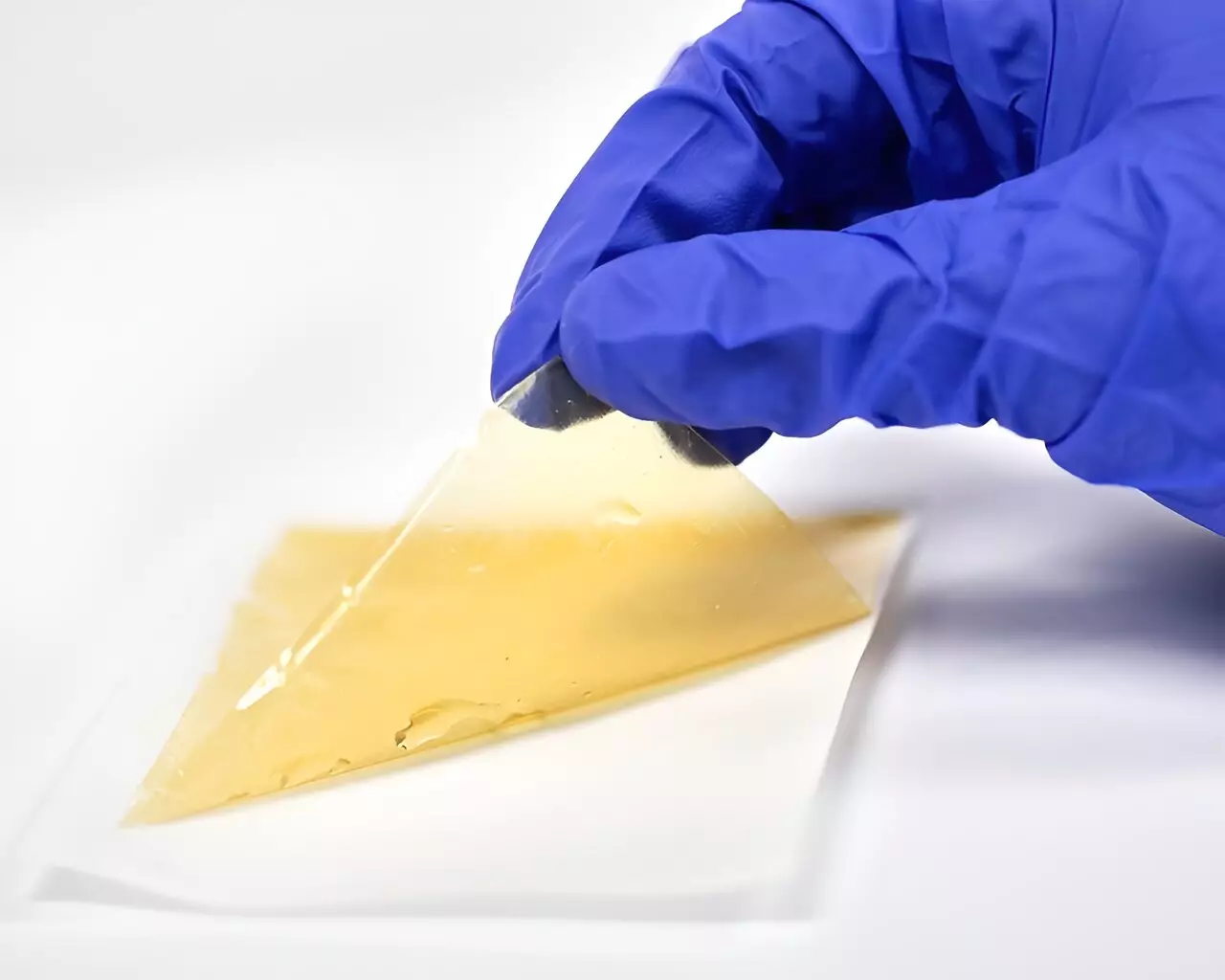

Led by Associate Professor Sang Moon Kim from Incheon National University and Professor Zhigang Suo from Harvard University, the research team focused on developing an electrolyte membrane that can withstand repetitive fatigue failure. The researchers utilized an interpenetrating network of Nafion and perfluoropolyether (PFPE) to create fatigue-resistant electrolyte membranes. Nafion, a commonly used plastic electrolyte, exhibits proton-conducting properties, while PFPE contributes to the durability of the membrane. Incorporating PFPE into the membrane slightly reduces electrochemical performance but significantly enhances fatigue threshold and lifespan.

The researchers produced several membranes with varying levels of PFPE and analyzed their electrochemical performance and lifespan. The Nafion-PFPE membrane with 50% saturation demonstrated reasonable electrochemical performance and showcased a significant improvement in fatigue resistance. Compared to the original Nafion membrane, the Nafion-PFPE membrane increased the fatigue threshold by 175% and extended the lifespan of the fuel cell by 1.7 times. The unmodified Nafion membrane exhibited a lifespan of 242 hours, while the composite membrane reached a lifespan of 410 hours. These results indicate that while the incorporation of the rubbery network slightly reduces electrochemical performance, the overall improvement in fatigue resistance and lifespan outweighs this drawback.

The development of fatigue-resistant electrolyte membranes holds considerable significance for numerous applications beyond fuel cell vehicles. The stability, durability, and performance offered by these membranes have the potential to revolutionize various industries. Apart from transportation, the technology can impact the development of advanced technologies in drones, personal air vehicles, backup power sources, forklifts, bicycles, scooters, and more. Furthermore, the strategy for enhancing fatigue resistance can be extended to other fields, such as ion filters, battery separators, and actuation systems. This opens up possibilities for high-durability and long-life desalination filters, flow battery separators, lithium metal battery separators, and artificial muscles. The wide range of applications demonstrates the far-reaching impact of this research.

The development of fatigue-resistant electrolyte membranes marks a significant advancement in the field of hydrogen fuel cell technology. The incorporation of an interpenetrating network of Nafion and PFPE has proven to enhance the durability and lifespan of fuel cells, overcoming the challenges posed by crack formation in the membrane. While there is a slight decrease in electrochemical performance, the overall benefits in terms of fatigue resistance and extended lifespan outweigh this drawback. The potential applications of these fatigue-resistant membranes extend beyond fuel cell vehicles, making way for innovations in various industries and opening up possibilities for the development of advanced technologies. With further research and refinement, these membranes could pave the way for a more sustainable and efficient future in energy production.

Leave a Reply