In recent years, advancements in manufacturing materials in space have opened up new possibilities for innovation. Through the experimentation conducted by a global team of researchers from various institutions, the process of creating materials in space rather than for space has been revolutionized. This breakthrough has the potential to pave the way for the development of materials that are not readily available on Earth. The team’s findings, which were published in the journal npj Microgravity, shed light on the atomic structure and arrangements of various kinds of glass that could be used for next-generation optical devices.

One of the key elements in the team’s research was the use of remote control manufacturing techniques in zero gravity. By leveraging levitators aboard the International Space Station (ISS), researchers were able to create and melt glass samples without interference from other materials. The unique environment of microgravity enabled the researchers to produce unconventional glasses that would be challenging to create on Earth. The use of a combination of techniques including neutrons, X-rays, and powerful microscopes allowed for the comparison of glass samples produced in space with those created terrestrially. This approach provided valuable insights into the differences in atomic structure and arrangement between the two.

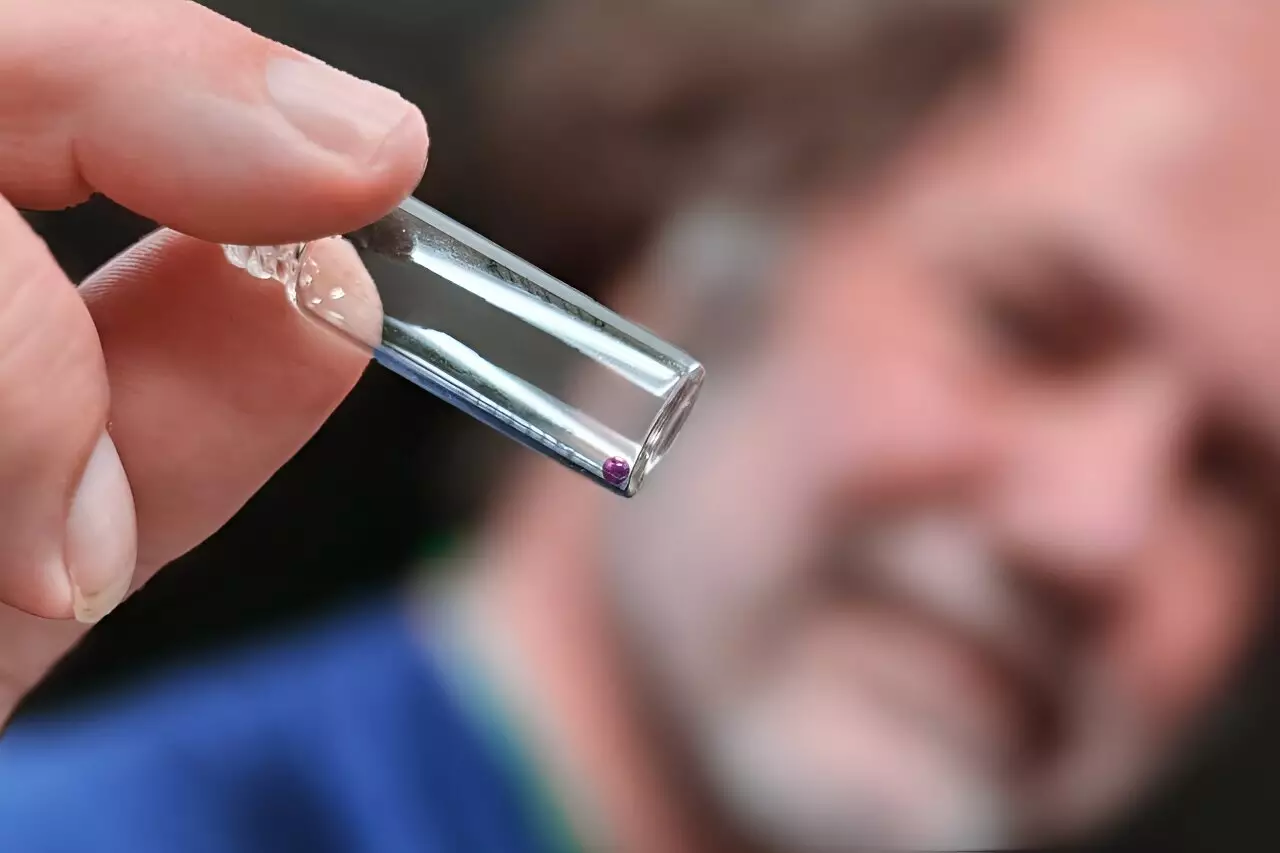

Glass, despite its seemingly simple appearance, possesses a complex and unique atomic structure. Unlike crystalline solids, glass does not exhibit a uniform structure, making its composition and arrangement more challenging to study. The research team’s experiments with glass samples containing neodymium and titanium oxides in 2022 revealed promising potential for optical applications. The discovery of a six-coordinate network in the glass composition opened up new possibilities for the development of optical materials and devices. By utilizing neutron and X-ray techniques, the researchers were able to analyze the atomic arrangements of lighter and heavier elements within the glass samples, providing valuable insights into the composition of space-manufactured glass.

Neutrons and X-rays have become essential tools in the study of materials, offering unique capabilities to analyze atomic structures. Neutrons were particularly useful in identifying the lighter elements present in the space glass, such as oxygen, while X-rays provided insights into the heavier elements like neodymium and titanium. By comparing the arrangement of atoms in the oxide sublattice and the distribution of heavy atoms in the glass samples, researchers were able to detect significant differences between space-manufactured glass and terrestrial glass. This multidisciplinary approach offered a comprehensive understanding of the impact of microgravity on material composition and formation.

The advancements in materials science through space-based manufacturing have far-reaching implications for future innovations. By harnessing the unique environment of zero gravity, researchers can develop novel materials with properties that are not achievable on Earth. The collaboration between institutions from around the world in conducting experiments in space has opened up new avenues for scientific discovery and technological advancements. The research conducted by the global team of scientists underscores the importance of innovation in manufacturing materials and the role of space exploration in driving scientific progress.

The future of materials science holds immense potential for breakthroughs in innovation through space-based manufacturing. By pushing the boundaries of scientific exploration and leveraging the tools available to study atomic structures, researchers are transforming the landscape of material development. As we continue to explore the possibilities of manufacturing materials in space, we are poised to unlock new discoveries and create technologies that will shape the future of our world.

Leave a Reply