When facing complex challenges, we often tend to overcomplicate our search for solutions. However, a recent study conducted by a research team at Pohang University of Science and Technology (POSTECH) revealed the power of simplicity in addressing the inherent issues of solid-state batteries. Led by Professor Byoungwoo Kang and Dr. Abin Kim from the Department of Materials Science and Engineering at POSTECH, the team developed a groundbreaking solid electrolyte with unique properties. Their findings, published in the journal ACS Energy Letters, showcased an ultra-thin lithium metal solid-state battery platform with exceptional stability and energy density.

The Complexity of Solid-State Batteries

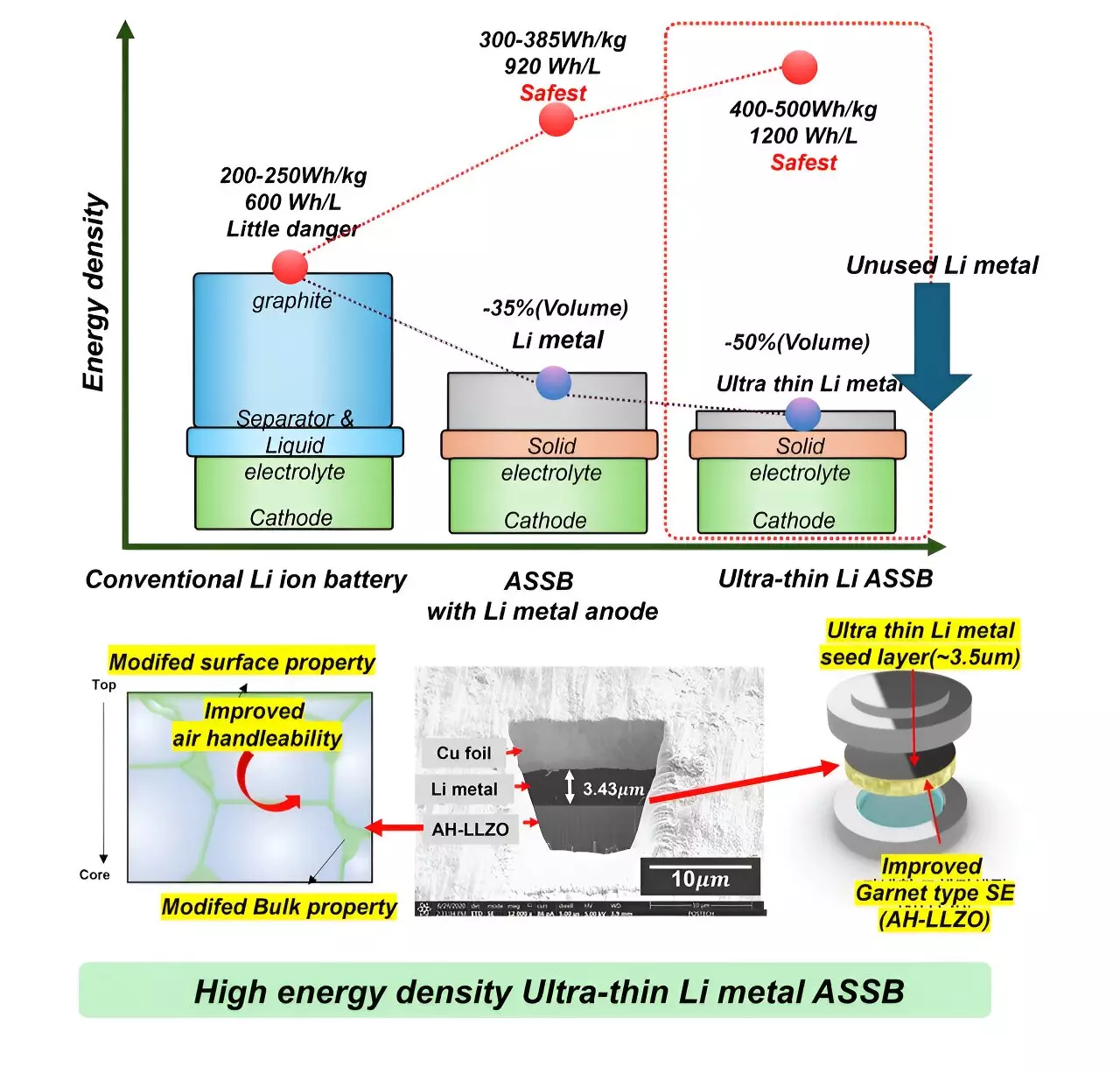

Solid-state batteries represent the next generation of battery technology, utilizing solid electrolytes instead of liquids to enhance energy density and safety. Among these, the garnet-type oxide solid electrolyte (Li7La3Zr2O12, or LLZO) has high ionic conductivity. However, LLZO is prone to forming a contamination layer (Li2CO3) on its surface when exposed to air, which acts as a barrier in cell construction, hindering contact and interfacial properties, particularly with the lithium metal anode. Current approaches involve coating the LLZO surface or implementing additional chemical or heat treatment processes post-synthesis, but these methods do not provide a permanent solution as the LLZO remains susceptible to contamination upon exposure to the atmosphere.

Taking a step back from conventional methods, the research team focused on enhancing the LLZO itself rather than relying on external coatings or post-processing techniques. By honing in on the core essence of the issue, they introduced an innovative technology known as air-handleable LLZO (AH-LLZO) that improved both the surface and internal properties of the solid electrolyte, effectively preventing the formation of contaminant layers from the outset. Through experiments, they successfully inhibited contamination layer formation by generating a new hydrophobic compound (Li-Al-O) on the surface and within the material, which mitigated reactions with moisture in the air, thus impeding the spread of contaminants internally.

The development of AH-LLZO technology enabled the research team to create ultra-thin lithium solid-state batteries with a thickness of approximately 3.43 μm, significantly reducing the capacity ratio of the anode to cathode to 0.176. This breakthrough not only minimizes the amount of lithium metal required but also enhances contact and wettability with lithium metal, thereby boosting energy density and overall battery performance. Moreover, the technology allows for storage in air without the need for specialized handling or facilities, streamlining the production process and increasing the practical applicability of garnet-type solid electrolytes.

The study conducted by Professor Byoungwoo Kang and his team at POSTECH exemplifies the importance of simplifying solutions in complex research endeavors. By focusing on the essence of the problem and developing an innovative approach to enhance solid-state batteries, they have paved the way for significant advancements in battery technology. Their work not only addresses the challenges of contamination in LLZO but also opens up new possibilities for improving energy density, performance, and practicality in battery applications.

Leave a Reply