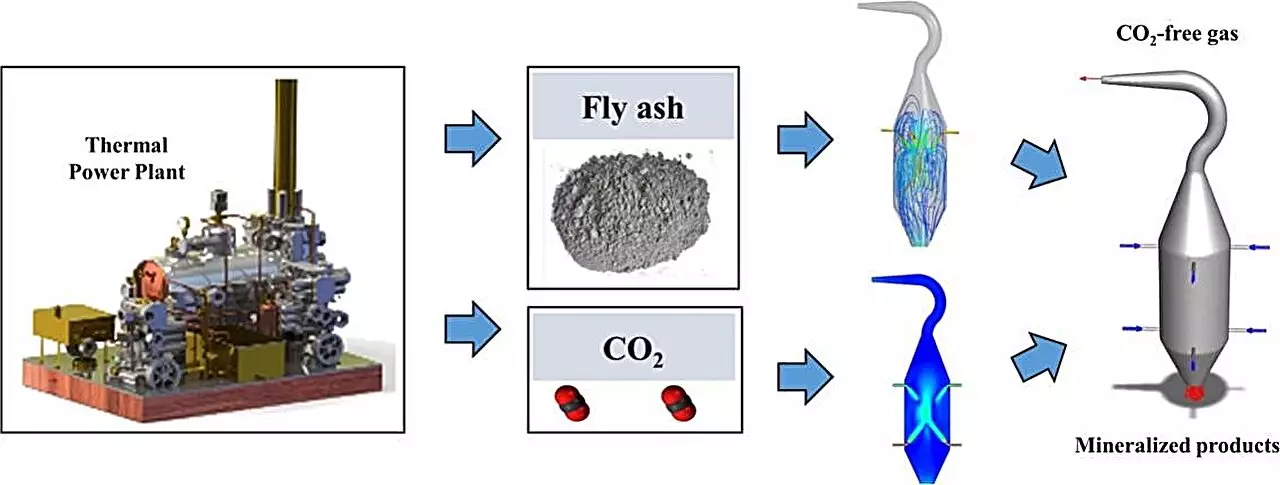

The conventional methods of waste management and CO2 sequestration are facing a significant challenge in the current scenario. The unprecedented increase in greenhouse gas emissions due to industrialization has created an urgent need for innovative solutions that can effectively tackle this pressing issue. In response to this challenge, researchers have developed reactors that utilize fly ash particles to mineralize carbon dioxide. This groundbreaking technique not only provides a sustainable solution for greenhouse gas emissions but also repurposes an industrial by-product, transforming waste into a valuable resource.

While existing carbon capture, utilization, and storage (CCUS) technologies have been instrumental in addressing CO2 emissions, they often struggle with issues related to efficiency and cost. The use of fly ash, a by-product of coal combustion, presents a promising opportunity for CO2 mineralization. However, the current reactor designs face obstacles in achieving optimal gas-particle interactions and operational efficacy. This necessitates a deeper exploration into innovative configurations and operational adjustments to enhance the overall performance of these reactors.

A recent study conducted by Shanghai Jiao Tong University, published in the Energy Storage and Saving journal, has introduced a novel approach to fly ash mineralization reactors. Through meticulous computational optimization, the research has unveiled two distinct reactor designs tailored specifically for CO2 mineralization using fly ash particles. The impinging-type inlet design emphasizes the enhancement of interfacial interactions, prolonging particle dwell times, and significantly increasing mineralization rates. On the other hand, the quadrilateral rotary-style inlet design prioritizes streamlined flow for improved mixing and reaction efficiency.

The study also delved into the exploration of various operational parameters such as flue gas velocity, carrier gas velocity, and particle velocity. Through rigorous investigations, optimal ranges for these parameters were identified, promising to elevate reactor performance to new levels. This optimization ensures efficient CO2 mineralization and facilitates phase separation post-reaction, further enhancing the overall efficacy of the process.

Dr. Liwei Wang, the principal investigator of the study, highlighted the significant advancements made in carbon capture and utilization technologies. The refined reactor designs and optimized operational parameters have resulted in a substantial improvement in CO2 mineralization efficiency. This progress not only benefits sustainable waste management but also offers a practical strategy for reducing industrial carbon emissions, in alignment with global climate action initiatives.

The implications of this research extend far beyond the laboratory, particularly for coal-fired power plants. By redirecting fly ash towards CO2 mineralization, this study presents a transformative solution to reduce carbon emissions and alleviate the environmental impact of fly ash disposal. The broader applications of this technology hold immense promise in harmonizing waste management practices with CO2 sequestration strategies, potentially redefining the approaches to CCUS technologies on a global scale.

Leave a Reply