Recent advancements in construction materials have continuously reshaped the landscape of structural engineering. Among these innovations, the development of ultra-high-performance concrete (UHPC) has emerged as a game-changer, primarily due to its superior strength and durability attributes. However, comprehending its full potential, particularly when confined by fiber-reinforced polymers (FRP), has presented significant challenges. A pivotal study led by renowned researchers, including S.S. Zhang and J.J. Wang from esteemed institutions, has introduced an analysis-oriented stress-strain model that aims to enhance the understanding and engineering applications of UHPC under FRP confinement.

Historically, engineering models have efficiently described the stress-strain relationships for normal-strength concrete (NSC) confined by FRP. Yet these conventional frameworks have proven inadequate when applied to UHPC. This discrepancy has been problematic, as UHPC offers numerous advantages but requires a fresh perspective to leverage its properties optimally. The intricacies of UHPC’s behavior under compression—especially when subjected to confinement—remain less understood, leading to a significant gap in the structural engineering field. Researchers’ investigation into this phenomenon marks a pivotal turning point in addressing these gaps.

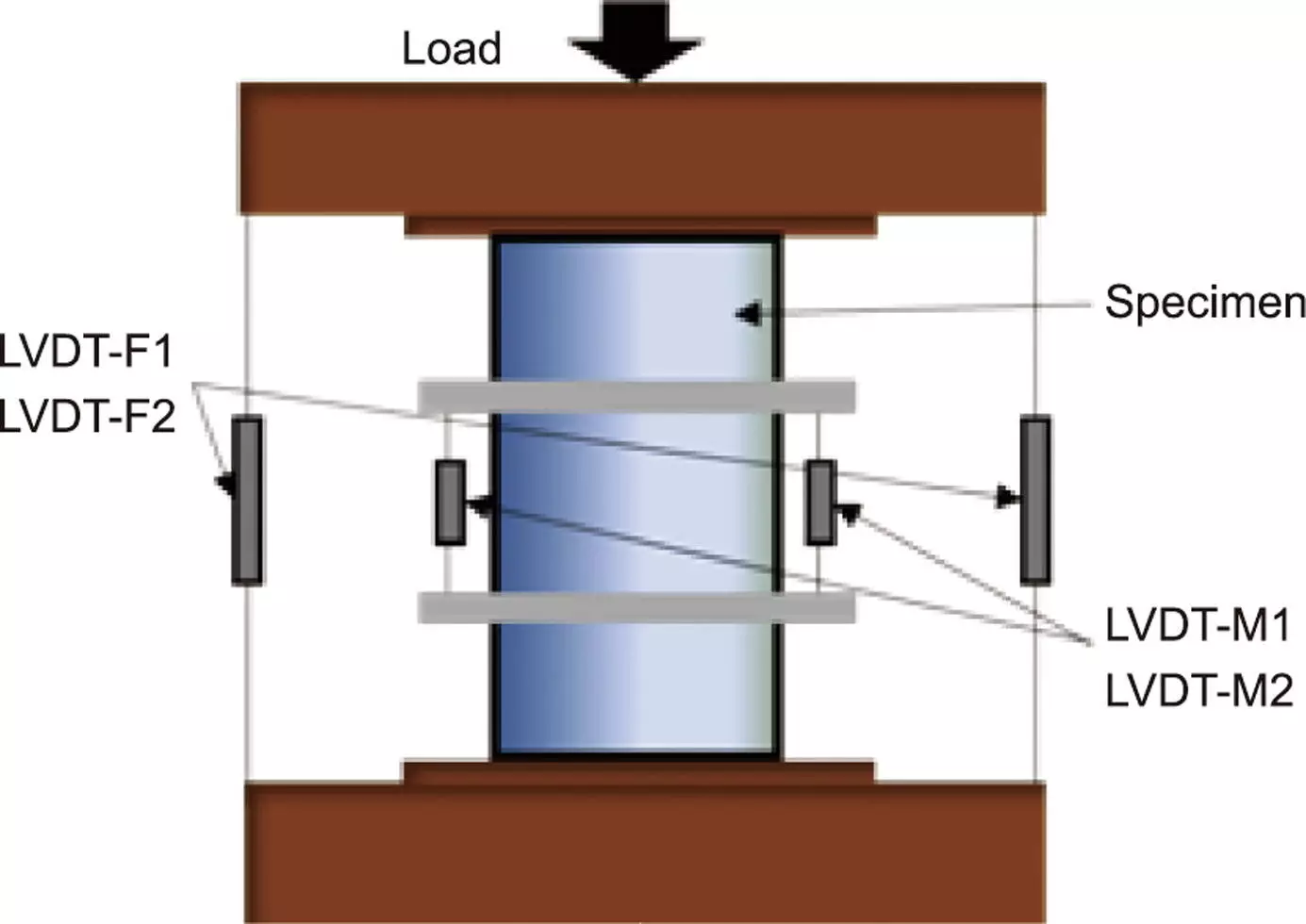

The research team conducted rigorous experiments to ascertain how UHPC reacts when confined by FRP materials under concentric compression. Their approach involved a meticulous examination of failure mechanisms that primarily affect the concrete’s integrity. Notably, the study revealed that the widely accepted stress-path-independency assumption, applicable to NSC, does not equate to UHPC’s behavior. One of the significant findings was that diagonal cracks often formed in the FRP-confined UHPC, leading to non-uniform lateral expansion. This situation resulted in diminished effective confining pressure, thereby complicating the traditional models previously employed.

As a result, the team re-evaluated and innovated the existing models to accommodate these new observations. An essential component of their revised approach was the inclusion of stress-path dependency, representing a significant shift in understanding UHPC’s response under stress. The modified model introduced equations to bridge the confining pressure gap, thus providing a more accurate representation of UHPC behavior.

Following its development, the new model underwent a rigorous validation process utilizing a comprehensive database of experimental results. This testing phase demonstrated its capacity to predict the stress-strain behavior of FRP-confined UHPC with remarkable precision. Such accuracy is a substantial advancement in the realm of structural engineering, providing engineers with a robust tool for designing more resilient UHPC structures.

By addressing the intricacies of stress-path dependency, this study has opened new avenues for research and application within the industry. The implications for construction are profound, signaling a potential shift towards more innovative and safer designs in structural applications using UHPC.

With the construction industry continually evolving, the insights garnered from this research are poised to significantly influence how engineers and researchers approach UHPC designs. The newfound understanding of its behavior under FRP confinement will likely enhance the performance and longevity of various comprehensive applications, fortifying structures against the stresses they encounter.

Moreover, this study invites a broader conversation about the development of new materials and design philosophies in structural engineering practices. The critical insights into the interplay between material properties and design methodologies could lead to innovative solutions and improved standards across construction projects, benefiting both designers and end-users.

The introduction of this analysis-oriented stress-strain model represents a substantial leap in our comprehension of UHPC confined by FRP. It provides invaluable tools for the engineering community, fostering innovation and improving the safety and efficiency of modern structural designs. This research underscores the ongoing need for scientific inquiry in construction materials and practices, offering a promising roadmap for the future of high-performance concrete applications.

Leave a Reply