The global transition towards a renewable energy future hinges significantly on the availability of rare-earth elements (REEs), particularly in technologies essential for sustainability, such as electric vehicles and wind turbines. The rising demand for these sophisticated technologies underscores an urgent need for efficient recycling methods to recover REEs from end-of-life products. A recent study from Kyoto University introduces a groundbreaking approach known as the selective extraction–evaporation–electrolysis (SEEE) process, which promises to reshape the landscape of REE recycling by addressing both efficiency and environmental concerns.

REEs, including neodymium (Nd) and dysprosium (Dy), play an indispensable role in the manufacturing of high-performance magnets. These materials are critical for the functionality of numerous green technologies, which explains the growing pressure on existing supplies. Traditional methods of extracting these elements typically involve complex hydrometallurgical techniques that are not only energy-intensive but also environmentally detrimental. Thus, the exploration of innovative recycling solutions that align with sustainability goals is essential.

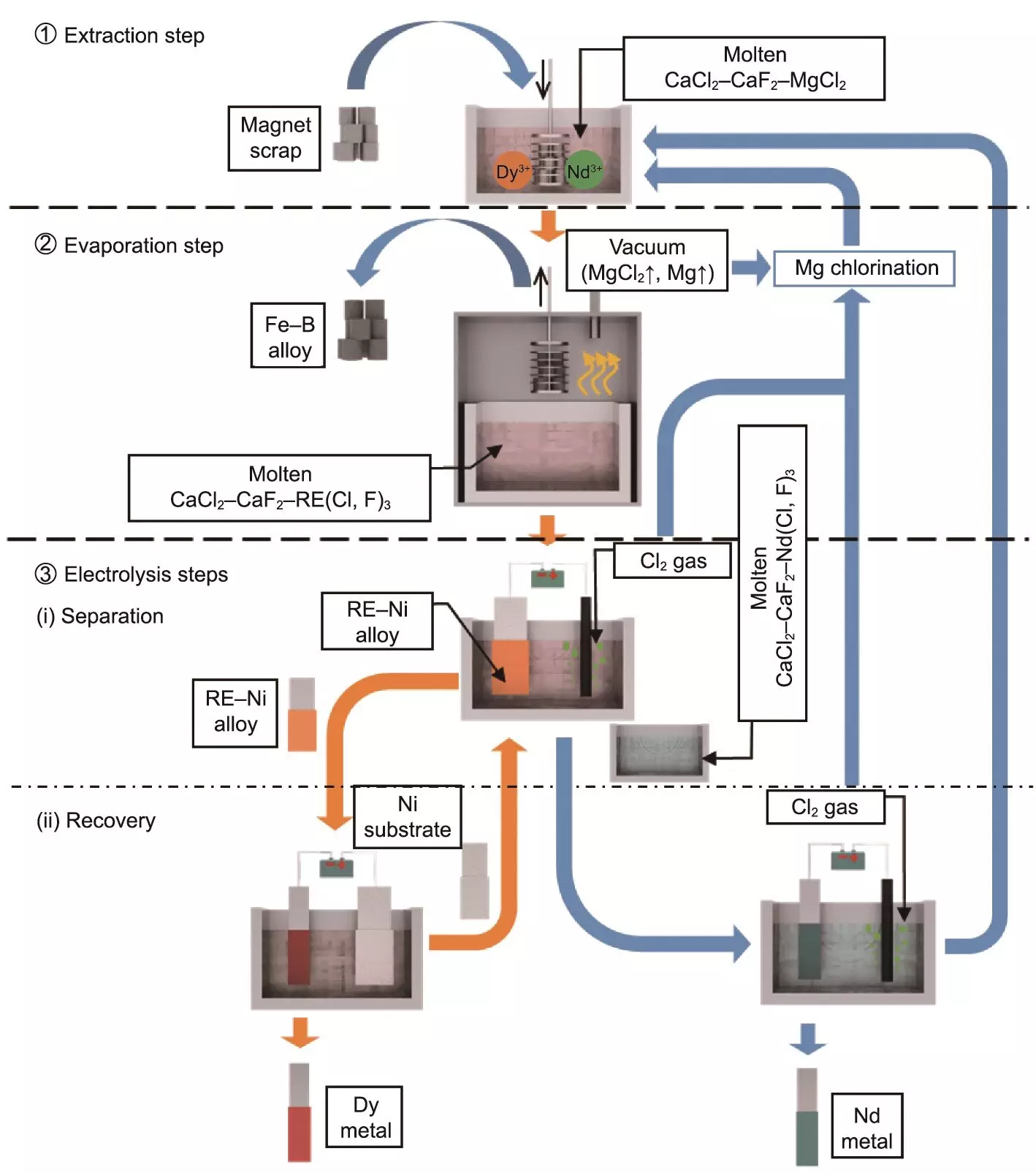

The SEEE process, primarily developed by Professor Toshiyuki Nohira and his team at the Institute of Advanced Energy, Kyoto University, represents a pivotal innovation in the recycling of Nd magnets. This novel methodology comprises three distinct stages which collectively enhance the recovery and purity of vital REEs.

1. **Selective Extraction:** The initial stage employs a molten salt mixture that includes calcium chloride (CaCl2) and magnesium chloride (MgCl2). This combination effectively extracts REEs from magnet remnants. The incorporation of calcium fluoride (CaF2) is crucial, as it mitigates evaporation losses, thereby improving the extraction efficiency.

2. **Selective Evaporation:** During this phase, the process meticulously eliminates leftover extraction agents and byproducts, concentrating the extracted REEs to refine the subsequent electrolysis stage.

3. **Selective Electrolysis:** The final phase leverages electrochemical methods to separate out the extracted REEs according to their distinct formation potentials, ultimately leading to the recovery of high-purity metals such as Nd and Dy.

The study’s findings are striking, with the SEEE process achieving remarkable recovery rates of 96% for Nd and 91% for Dy, both at purities exceeding 90%. This represents a substantial improvement over conventional methods, pointing to the SEEE process as not just effective but also a sustainable alternative. By delivering a process that minimizes energy expenditure and environmental impact, this innovation could alleviate some of the urgent pressures on natural REE reserves.

With the escalating necessity for electric vehicles and renewable energy technologies, the SEEE process emerges as a sustainable solution that could safeguard the supply chain for critical materials. By reducing reliance on the environmentally taxing mining processes traditionally used to obtain REEs, the SEEE method stands to contribute positively to global environmental directives aimed at combating climate change.

What makes the SEEE process particularly exciting is its versatility. While initially focused on Nd magnets, researchers suggest the technology’s adaptability could extend to various sectors, including potential applications in the reprocessing of nuclear fuels. Such versatility opens doors to widespread utilization in areas where material recovery is crucial, enhancing overall sustainability across multiple industries.

Despite its promising initial success, the researchers acknowledge that further technical enhancements are necessary for the SEEE process to be seamlessly integrated into industrial practices. Nevertheless, the introduction of this innovative method indicates a hopeful direction for future advancements in material recycling.

The research coming from Kyoto University highlights not only the critical role of technological advancements in resolving material recycling challenges but also emphasizes the importance of continued exploration in this field. As societies leverage the potential of green technologies for a sustainable future, innovations such as the SEEE process will be pivotal in aligning progress with environmental stewardship. Ongoing efforts in research and development will be essential to ensure that the transition toward a carbon-neutral world is not only viable but also achievable.

Leave a Reply