As global environmental concerns continue to escalate, the quest for sustainable solutions in battery technology has gained significant momentum. Traditional lithium-ion batteries, widely used in consumer electronics and electric vehicles, often depend on fluorinated components that pose serious environmental risks. This reliance raises pressing questions about the sustainability of materials in battery production, with researchers increasingly focused on developing alternatives that satisfy both performance requirements and ecological considerations.

The recent efforts by a research team from POSTECH and Hansol Chemical have set a groundbreaking precedent in this domain, as they unveil a new fluorine-free binder and electrolyte system that promises to revolutionize battery technology. Their findings, published in the Chemical Engineering Journal, underscore the urgent need for innovation in battery materials that align with stricter regulations targeting harmful substances.

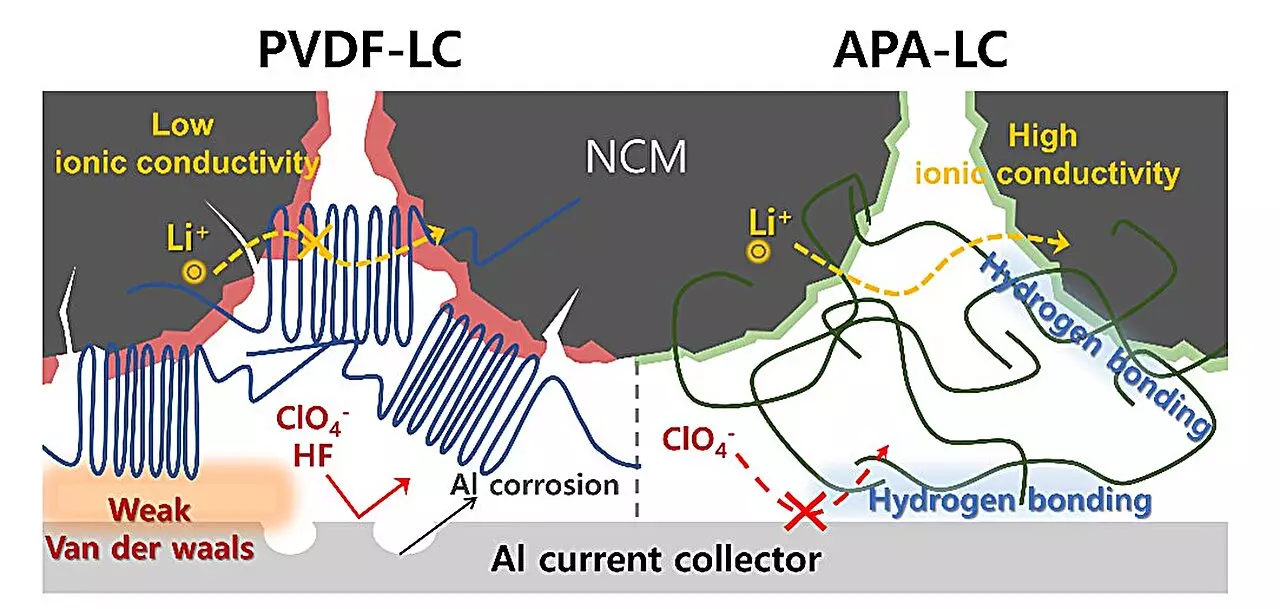

The conventional framework of lithium batteries often employs polyvinylidene fluoride (PVDF) for binding and lithium hexafluorophosphate (LiPF6) as an electrolyte. While these materials have served the industry for years, they come with significant downsides. The central issue lies in the production and decomposition of these fluorinated components, which release hydrogen fluoride (HF)—a highly toxic gas that not only poses health hazards but also compromises battery performance and longevity.

Moreover, PVDF’s non-biodegradable nature is increasingly at odds with global environmental initiatives. With regulatory bodies like the European Union pushing for a ban on per- and polyfluoroalkyl substances (PFAS) by 2026, the time for an alternative solution is rapidly running out.

Taking a proactive stance, the team led by Professor Soojin Park and Seoha Nam has developed a new battery system that avoids fluorinated materials altogether. By replacing the traditional PVDF-LP system with a lithium perchlorate (LiClO4)-based electrolyte and a non-fluorinated aromatic polyamide (APA) binder, the research underscores the potential of the “APA-LC” system to meet impending regulatory challenges while enhancing overall battery performance.

The distinctive functionality of the APA binder lies in its ability to form robust connections between cathode active materials and the aluminum current collector. This delivery of strength not only reduces the risk of electrode degradation but also extends the lifespan of the battery. The enriched LC electrolyte, featuring lithium chloride (LiCl) and lithium oxide (Li2O), further facilitates faster ion migration, which optimizes energy output and ensures superior performance compared to legacy systems.

The research team’s achievements go beyond theoretical models; they successfully produced a high-capacity 1.5 Ah pouch cell that exhibited remarkable discharge capacity and resilience during fast-charging scenarios. This prototype stands as the world’s first fully scalable battery solution devoid of fluorinated materials, setting a new benchmark for future developments in the battery industry.

The results demonstrate that the APA-LC system retains 20% greater capacity after 200 charge/discharge cycles at a rapid 1 C rate—a significant improvement over its predecessor. Such findings not only indicate promising commercial viability but also reflect an essential shift toward more sustainable battery technologies that can help reduce environmental footprints.

Industry stakeholders have expressed optimism about the ramifications of this research. According to Managing Director Young-Ho Yoon of Hansol Chemical’s Secondary Battery Materials Division, their breakthrough positions them favorably within the global cathode binder market, which is anticipated to significantly grow. As regulatory pressures mount, the push for eco-friendly materials offers both a challenge and an opportunity for companies focused on alignment with environmental standards.

Professor Park’s emphasis on high-capacity retention and stability reveals that these advancements are not merely a stopgap measure; they signify a genuine commitment to embedding sustainability within the framework of battery production.

The collaborative work between POSTECH and Hansol Chemical sets a promising precedent in the search for environmentally friendly alternatives in battery technology. As the interplay between innovation, regulation, and environmental stewardship unfolds, the battery industry may well stand on the cusp of a transformative era, driven by the imperative of ecological responsibility.

Leave a Reply