In a groundbreaking development, a research team led by Dr. Sung Mook Choi at the Korea Institute of Materials Science has introduced a one-step electrode fabrication process in South Korea. This innovative approach, detailed in the journal Applied Energy, marks a significant milestone in the field of anion exchange membrane water electrolysis.

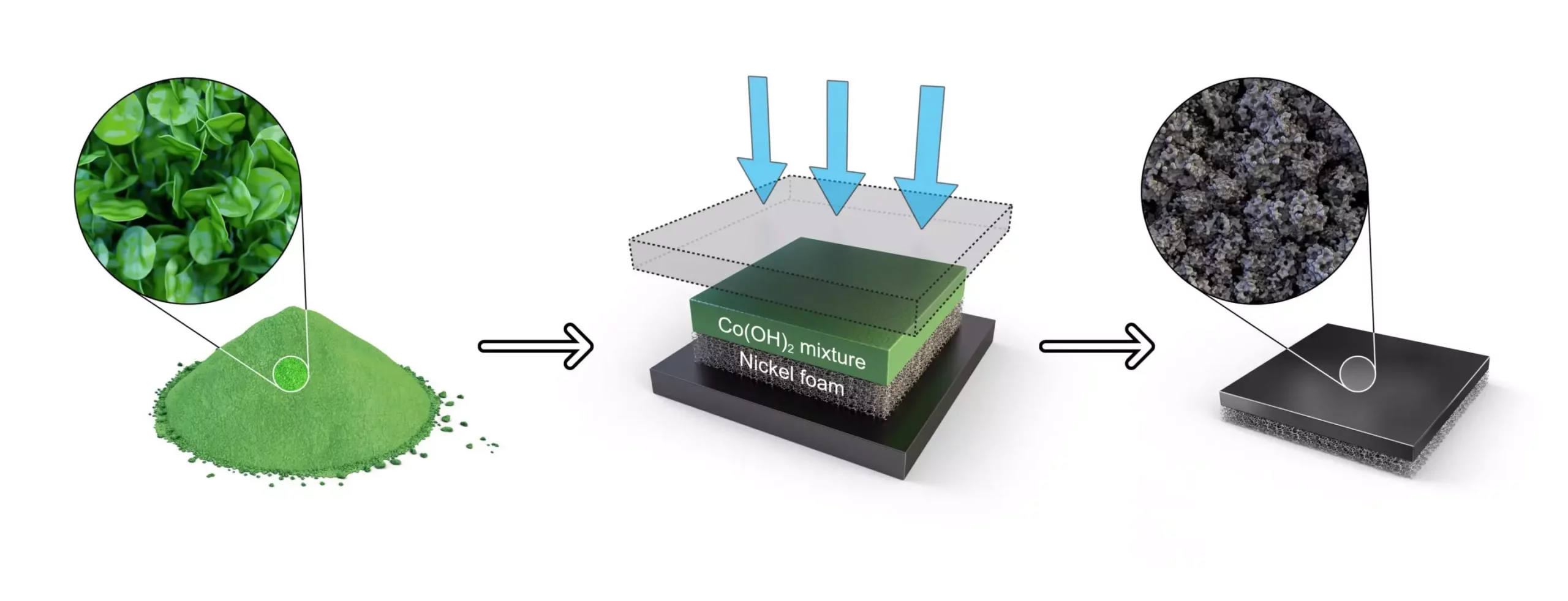

The new technology streamlines the production of electrodes, a crucial component of anion exchange membrane water electrolysis, by directly converting raw materials into mass-producible electrodes. Unlike traditional methods that involve multiple complex steps, such as hydroxide-oxide-crushing-dispersion-coating-drying, this one-step hot-pressing process simplifies the fabrication process by 60%, resulting in a more uniform catalyst layer. The process converts cobalt hydroxide into a cobalt oxide catalyst, while also forming a highly uniform catalyst layer, thereby improving efficiency of hydrogen production and durability during continuous operation.

To enhance the effectiveness of the one-step electrode fabrication process, the research team meticulously controlled the cobalt hydroxide slurry conditions, as well as temperature and pressure during the hot-pressing process. By producing a catalyst layer with uniform oxide particles measuring 10 nanometers in size, the team successfully created a membrane electrode assembly (MEA) incorporating an anion exchange membrane and a hydrogen evolution catalyst. The stability and performance of the developed electrode were further validated in a commercial-scale water electrolysis cell.

The successful application of the developed electrode in an anion exchange membrane water electrolysis system holds paramount significance in the realm of green hydrogen production. With projections indicating a substantial increase in green hydrogen production by 2030, the need to advance water electrolysis technology is more pressing than ever. Efforts are underway in Korea to develop technology for a megawatt-level anion exchange membrane water electrolysis system by 2024, with plans for commercialization by 2030. Currently, Korea’s anion exchange membrane water electrolysis technology stands at 70-80% of global standards, necessitating further investment in research and development.

Dr. Sung Mook Choi, the principal researcher behind this groundbreaking technology, emphasized the significance of the one-step hot pressing electrode fabrication process in overcoming key challenges related to the commercialization of anion exchange membrane water electrolysis. By securing core original technology and localizing the fabrication process, Korea aims to establish a global leadership position in water electrolysis technology, paving the way for sustainable and efficient hydrogen production in the years to come.

Leave a Reply