The development of robots for complex maintenance tasks has been a promising area of research for engineers. However, many of these robots have been limited in their real-world application due to the need for external power sources. This limitation has sparked a new wave of innovation aimed at creating wireless miniature robots that can navigate through pipes and tubular structures without relying on external power.

Researchers at the Max Planck Institute for Intelligent Systems, Harbin Institute of Technology, and Hong Kong University of Science and Technology have successfully developed a new wireless millimeter-scale robot that can operate independently within tubular structures. Unlike previous models, this robot includes an internal power source and an actuation unit, allowing it to cover longer distances and perform maintenance tasks for extended periods without the need for external power.

Key Components of the Robot

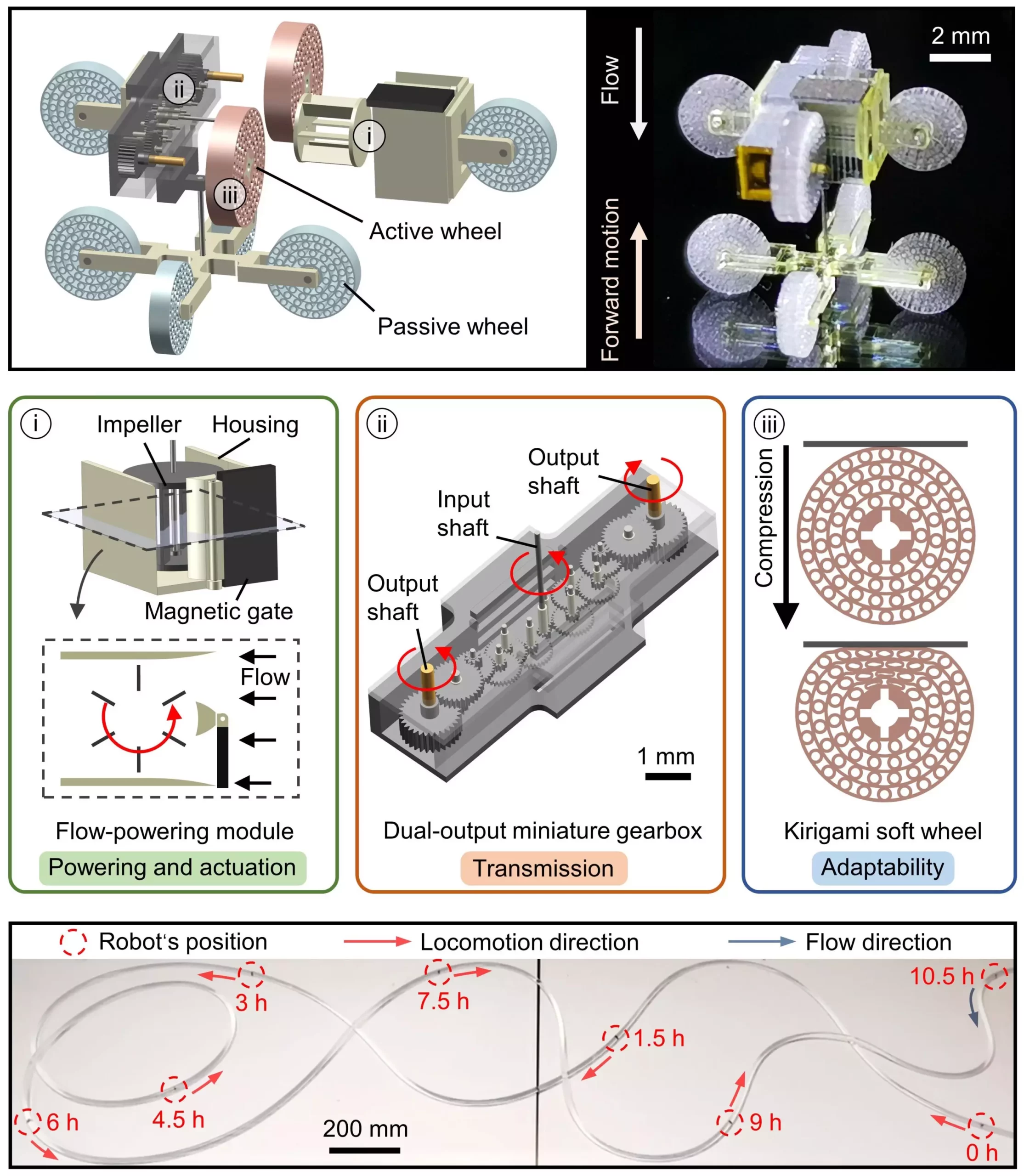

The wireless millirobot created by the researchers incorporates three key components: a flow-powering module, a dual-output miniature gearbox, and kirigami soft wheels. These components work together to convert flow power into mechanical energy, enabling the robot to navigate through complex pipelines with ease. The internal impeller of the robot can modulate its direction simply by applying an external magnetic field, making it versatile and adaptable to different situations.

In preliminary tests, the researchers found that the wireless millimeter-scale robot performed well and showed promising results. However, they acknowledge the need to further enhance its capabilities and stability to ensure its successful deployment in real-world settings. One area of improvement includes streamlining the robot body to minimize flow resistance or adding microstructures to the wheel surfaces to increase friction, especially in high-flow rate environments or low-friction surfaces like oil pipelines.

Moving forward, the researchers plan to continue refining the wireless millirobot to meet the demands of long-distance navigation and maintenance tasks within confined tubular structures. They aim to enhance the robot’s anchoring force and motion status switching capabilities, potentially by improving the design of the robot body and incorporating new technologies to maximize its performance in various environments. By doing so, they hope to revolutionize the field of maintenance with the integration of wireless miniature robots.

Leave a Reply