As the demand for sustainable energy storage solutions escalates, researchers are increasingly spotlighting sodium-ion batteries as a viable alternative to traditional lithium-ion batteries. The growing pursuit of environmentally friendly alternatives is fueled by concerns over lithium mining impacts and the finite availability of lithium sources. Sodium, abundant and cheap, is gaining attention for its potential to replace lithium in battery technologies. However, while its availability is a strong advantage, sodium-ion batteries have struggled with performance metrics, mainly energy density and lifespan, when juxtaposed against their lithium counterparts.

At the heart of sodium-ion battery technology lies the anode material, which is a critical component affecting overall battery performance. Unlike lithium-ion batteries that utilize graphite, sodium-ion batteries require hard carbon owing to the larger size of sodium ions. This necessity presents a manufacturing challenge, as hard carbon is not organically available but must be synthesized through a convoluted process involving high-temperature carbonization. Typically, the preparation involves heating hydrocarbon materials in oxygen-free environments to temperatures exceeding 1,000 degrees Celsius. This method not only proves economically expensive but also poses environmental challenges, hindering the commercial viability of sodium-ion batteries.

Innovative Microwave Induction Heating Technology

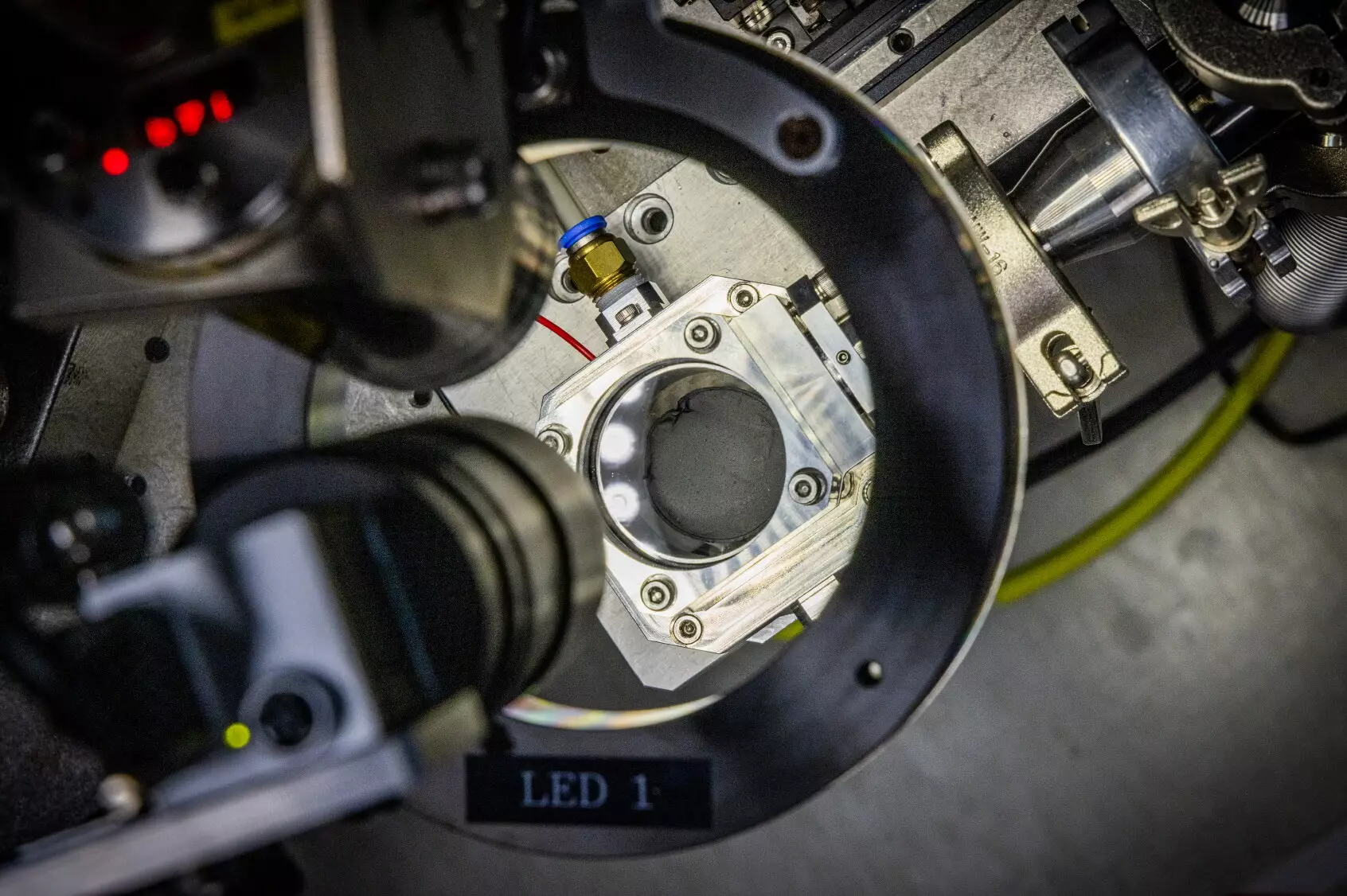

A ray of hope comes from a pioneering research team led by Dr. Daeho Kim and Dr. Jong Hwan Park at the Korea Electrotechnology Research Institute (KERI). Their innovative approach employs microwave induction heating, significantly reducing the time required for preparing hard carbon anodes to a mere 30 seconds. By leveraging everyday microwave technology, they demonstrated that films made from polymers infused with conductive carbon nanotubes can be heated uniformly to temperatures beyond 1,400 degrees Celsius using electromagnetic fields. This breakthrough not only streamlines the production process but has the potential to substantially enhance energy efficiency and reduce costs associated with hard carbon synthesis.

The team’s success is largely attributed to their proprietary “multiphysics simulation” technique. This methodological approach enabled them to gain insights into the complex interactions occurring within nanomaterials when exposed to microwave energy. Understanding electromagnetic behaviors at such intricate levels has proven pivotal in fine-tuning the parameters of the heating process, thus optimizing the production of anode materials for sodium-ion batteries. The publication detailing their findings in the Chemical Engineering Journal, co-authored by budding researchers Geongbeom Ryoo and Jiwon Shin, marks a significant milestone in collaboration between academia and research institutions, fostering an environment conducive to innovation.

With the automotive industry grappling with issues related to battery safety, especially fiery incidents linked to lithium-ion batteries, the shift towards sodium-ion batteries appears favorable. These new batteries are not only expected to be safer but also perform reliably in adverse weather conditions, making them ideal candidates for use in electric vehicles. Dr. Park emphasizes that the cumbersome nature of the traditional carbonization process poses significant energy losses, a challenge that their new microwaving technology addresses head-on.

Looking ahead, the research team’s ambitions extend beyond refining anode performance. They are committed to developing methods for mass production of large-area hard carbon films, thereby facilitating industrial scalability. Moreover, the techniques honed through this project may have broader implications, potentially revolutionizing other battery technologies, such as all-solid-state batteries that require high-temperature sintering.

The reception of KERI’s microwave induction heating technology has already elicited interest from various sectors, particularly those centered on energy storage solutions. In anticipation of potential partnerships, KERI has initiated domestic patent applications to protect this groundbreaking technology. Collaborating with industry players holds promise for expediting the commercial rollout of sodium-ion batteries, a development that could reshape the energy storage landscape substantially.

The research team at KERI is at the forefront of a technological shift that could elevate sodium-ion batteries as a formidable alternative in the energy storage domain. With economically viable, environmentally friendly production methods and the promise of enhanced performance qualities, microwave induction heating may indeed be the game-changer the market has been yearning for. As they pursue further advancements and potential collaborations, the influence of their innovations could resonate well beyond conventional battery applications, ushering in a new era of materials science and energy solutions.

Leave a Reply