Boston Dynamics is at the forefront of technological advancement, aiming to embed its all-electric humanoid robot, Atlas, within the production lines of a Hyundai factory later this year. This strategic initiative marks a pivotal shift in how robotics are integrated into commercial manufacturing. The Atlas robot, an upgraded version of its hydraulic predecessor, emerged from years of meticulous engineering and public demonstrations that have captured the imagination since 2013. Unlike previous iterations limited to experimental ambulation, the upcoming deployment signifies a profound leap towards practical, real-world applications of humanoid robotics in industry.

Humanoid robots have long existed within the confines of research laboratories, showcasing their capabilities through controlled environments. Yet, Atlas’s work with Hyundai offers a glimpse into a future where these machines can perform as reliable assistants to human workers, undertaking tasks that are either beyond human physical capabilities or simply too arduous for individuals. Kerri Neelon, a spokesperson for Boston Dynamics, emphasizes the potential of Atlas to assist in challenging environments by handling heavy and awkwardly shaped objects, thereby optimizing labor efficiency.

Commercial Viability and Industry Expansion

The impending integration of robots like Atlas into commercial manufacturing surfaces significant implications for the industry landscape. Boston Dynamics’s move represents not just innovation but also a potential disruption of traditional manufacturing practices. Automated systems confined to specific tasks on the assembly line could soon be complemented—or even replaced—by humanoid robots capable of multitasking across various operations, reflecting a more human-like versatility.

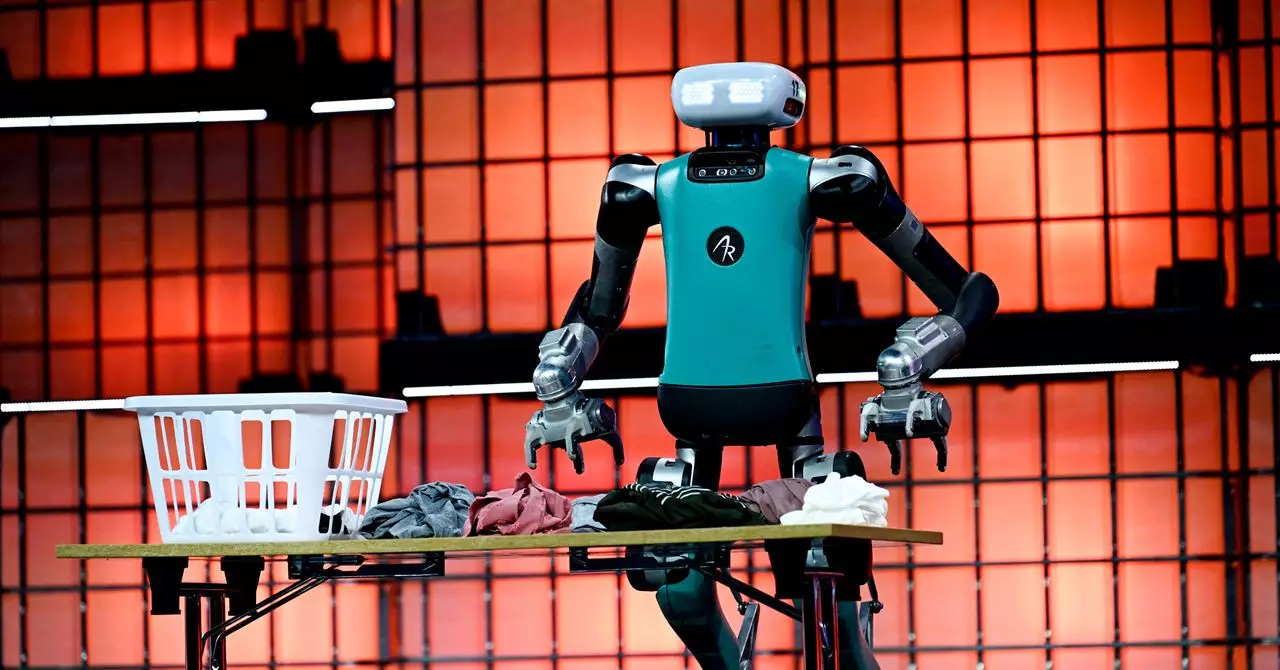

Other players in the sector are also acknowledging the momentum. The emergence of companies like Agility Robotics and Figure has showcased robots like Digit and their early adaptations in warehouse settings. Robots are no longer burgeoning curiosities but are indeed stepping into the workforce, as evidenced by predictions that the market for humanoid robots will reach a staggering $38 billion by 2035, a figure reflecting a steep upward trend in interest and investment.

The essential advantage of humanoid robots is their ability to transition between multiple roles, a flexibility that significantly contrasts with predefined automation systems. Jonathan Hurst, co-founder of Agility Robotics, articulates a lucid perspective: while specialized automation retains supremacy in high-demand, repeat operations, humanoid robots excel in adaptability for less rigid tasks, effectively supplementing human labor without outright replacement.

The Human-Centric Design Paradigm

One of the most compelling aspects of the Atlas project is its philosophical foundation. Boston Dynamics has committed to designing robots that harmonize with human-centric environments. This perspective resonates with the idea of fostering a workspace that prioritizes safety and efficiency for human teammates. Neelon’s assertion that “we live in a human-first world” underscores the intent to create robots that not only exist in the same space as humans but also work synergistically with them.

This integration, however, is not without its challenges. The debut of Tesla’s Optimus has showcased both the excitement and the skepticism surrounding humanoid technology. Concerns have surfaced regarding the autonomy of such robots, particularly following demonstrations that revealed a reliance on human operators. Elon Musk’s timelines promise ambitious production numbers, yet the complexities of supply chains and international dependencies—especially concerning rare-earth metals—might complicate these aspirations.

Future Challenges and Opportunities

The road ahead for humanoid robots remains fraught with both challenges and opportunities. While the promise of humanoid versatility is compelling, tangible consumer and commercial application will require overcoming significant technical and regulatory hurdles. Factors such as evolving legislation, safety protocols, and public perception will heavily influence the adoption of these advanced machines in everyday settings.

As industries explore the capacity of humanoid robots like Atlas, they must also grapple with questions of ethics, workforce displacement, and the broader societal impacts. While the potential for increased productivity and efficiency is evident, the need for a balanced approach that considers the human element in the workforce cannot be overstated. In light of these developing dynamics, the coming years will reveal whether humanoid robots can fully transform industries or remain bound to the periphery as curiosities introduced into the factory environment.

Leave a Reply