University of Toronto Engineering researchers have developed a groundbreaking catalyst that efficiently converts captured carbon into valuable products. This discovery represents a significant advancement in the field of carbon capture and storage, offering more economically favorable techniques that can be seamlessly integrated into existing industrial processes.

While current catalysts have been successful in converting CO2 into useful products, they often struggle when faced with impurities in the carbon feed. Impurities such as sulfur oxides can quickly degrade the catalyst’s performance, reducing efficiency and hindering the conversion process. This poses a significant challenge for industries like steel and cement manufacturing, which produce carbon-rich waste streams that are not pure.

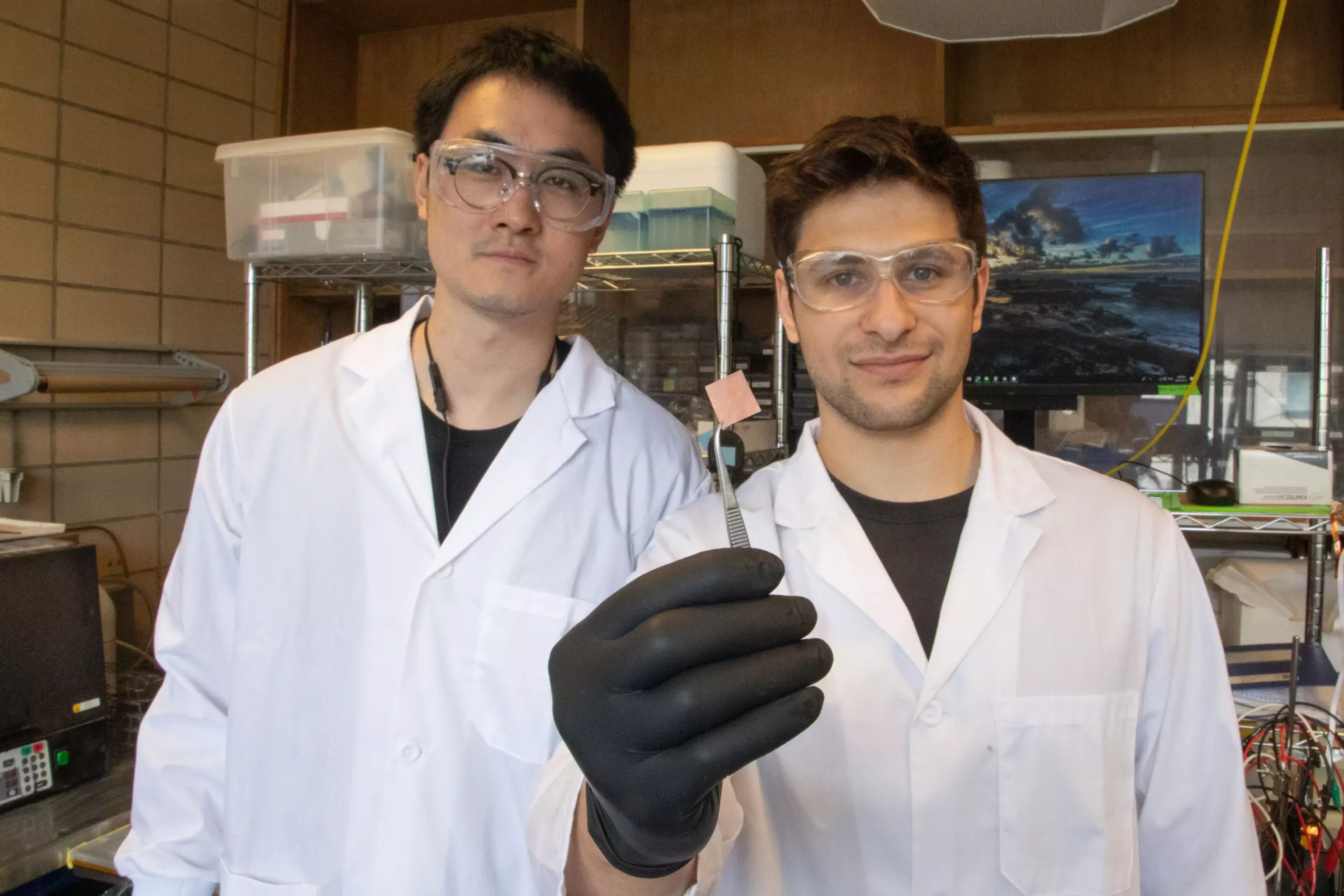

The team of researchers led by Professor David Sinton addressed these challenges by designing a more resilient catalyst. By making two key modifications to a typical copper-based catalyst, they were able to enhance its performance in the presence of impurities. The addition of a thin layer of polyteterafluoroethylene and a layer of Nafion improved the catalyst’s resistance to sulfur oxide poisoning, enabling it to maintain efficiency even under challenging conditions.

The newly designed catalyst was tested with a mix of CO2 and sulfur oxides, simulating conditions found in industrial waste streams. Despite the presence of impurities at typical concentrations, the catalyst maintained a high Faraday efficiency of 50% for 150 hours. This level of performance is a significant achievement, as other catalysts often experience a rapid decline in efficiency when exposed to impurities.

One of the key advantages of this new catalyst design is its adaptability to existing high-performing catalysts. By incorporating similar coatings, other research teams can enhance their catalysts’ resistance to sulfur oxide poisoning without altering their composition. This opens up new possibilities for tackling a wide range of impurities in carbon-rich waste streams and streamlining the carbon conversion process.

The development of a more resilient catalyst for carbon conversion marks a crucial step forward in advancing carbon capture and storage technologies. By addressing the challenges posed by impurities in industrial waste streams, researchers have paved the way for more efficient and cost-effective methods of converting captured carbon into valuable products. This innovative approach holds promise for industries seeking sustainable solutions for reducing their carbon footprint and transitioning to a low-carbon future.

Leave a Reply