Ethylene (C2H4) is a compound with diverse applications, from packaging to agriculture. The conventional methods used for ethylene production, such as fossil-powered steam cracking of ethane, are energy-intensive and environmentally harmful. However, a recent study by researchers at Soochow University and University of Toronto introduced a new approach to produce ethylene sustainably.

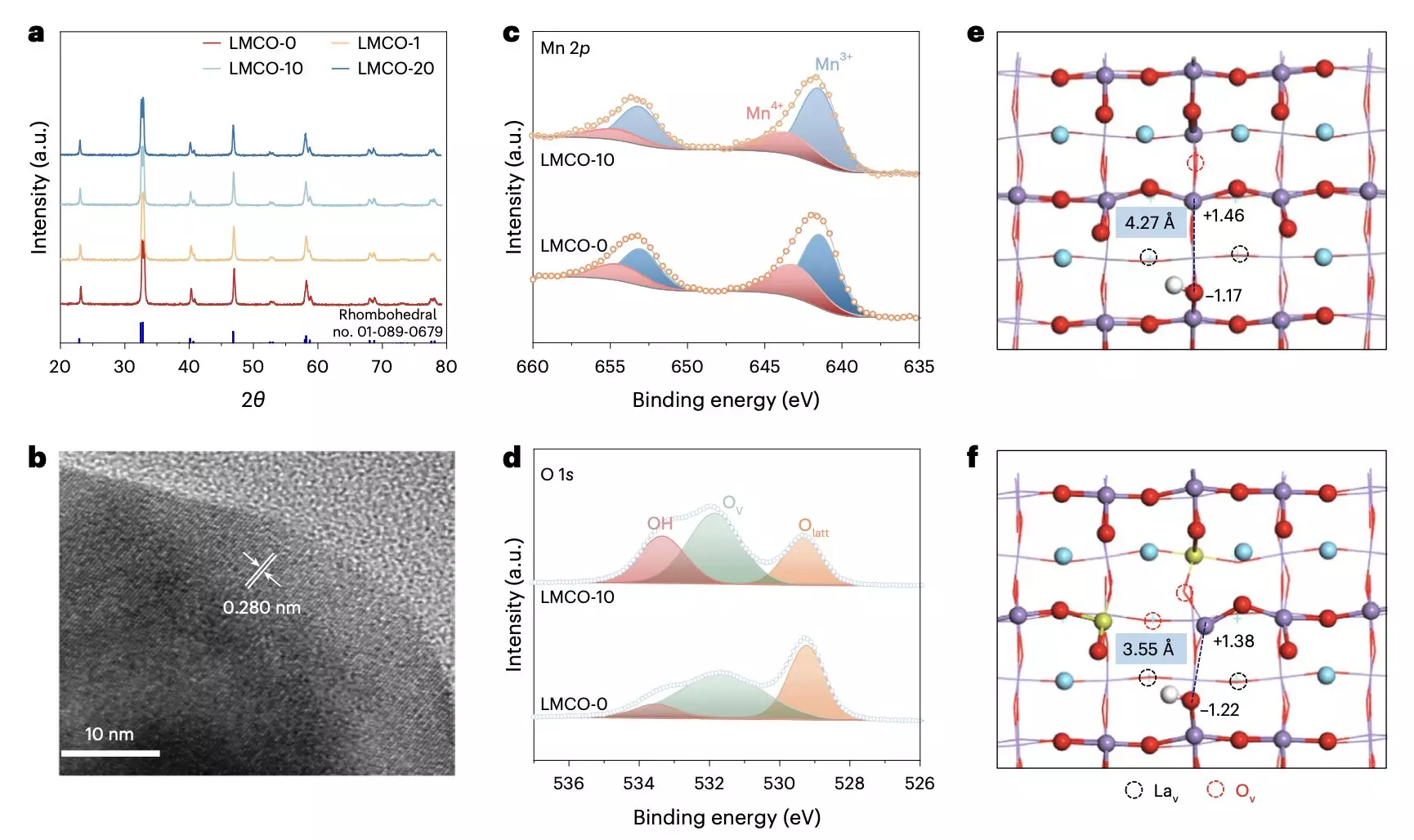

The researchers utilized a perovskite oxide, LaMn1−xCuxO3, as a photocatalyst to convert ethane into ethylene and hydrogen using solar or LED light. This innovative approach eliminates the need for external heat sources, resulting in lower carbon emissions. The perovskite oxide’s unique properties, such as redox-active Lewis acid and base sites, optimize the ethane dehydrogenation process.

Through their experiments, the researchers demonstrated high ethylene production rates using a rooftop prototype device. The technical and economic analyses conducted highlighted the significant economic potential of this solar-powered ethylene production method. The successful demonstration of a simple outdoor prototype showcases the viability of implementing this sustainable approach on an industrial scale.

To enhance the efficiency of the ethylene production process, further engineering of the photocatalyst and photoreactor is essential. The researchers plan to deepen their investigations into the performance of the photocatalyst and photoreactor, focusing on their impact on catalytic reactions. Additionally, improvements in photochemical activation, light capture, and light transport rates are necessary to maximize the perovskite’s photocatalytic efficiency.

The development of a solar-powered photocatalytic dehydrogenation process for ethylene production represents a significant step towards a sustainable future. By leveraging the unique properties of the LaMn1−xCuxO3 perovskite oxide, researchers have successfully demonstrated a more environmentally friendly alternative to traditional ethylene production methods. The continued research and optimization of this innovative approach hold great promise for reducing greenhouse gas emissions and meeting the increasing demand for ethylene in a more sustainable manner.

Leave a Reply