The construction industry is encountering numerous challenges in the current scenario. The depletion of natural sand, which is projected to vanish by 2050, presents a looming threat. Additionally, the escalating carbon dioxide emissions from the production of cement and fired clay bricks are a pressing concern. Furthermore, the volume of construction and demolition (C&D) waste is steadily increasing, with a recycling rate of only 1% in India. These challenges necessitate immediate attention and innovative solutions to ensure the sustainable growth of the construction sector.

Researchers at the Center for Sustainable Technologies (CST) at the Indian Institute of Science (IISc) have embarked on a mission to address these challenges through groundbreaking research. Their focus lies in exploring methods to capture and store carbon dioxide from industrial flue gas in excavated soil and C&D waste. By utilizing these materials to partially replace natural sand, not only can the environmental impact of construction materials be reduced, but their properties can also be enhanced for improved construction applications.

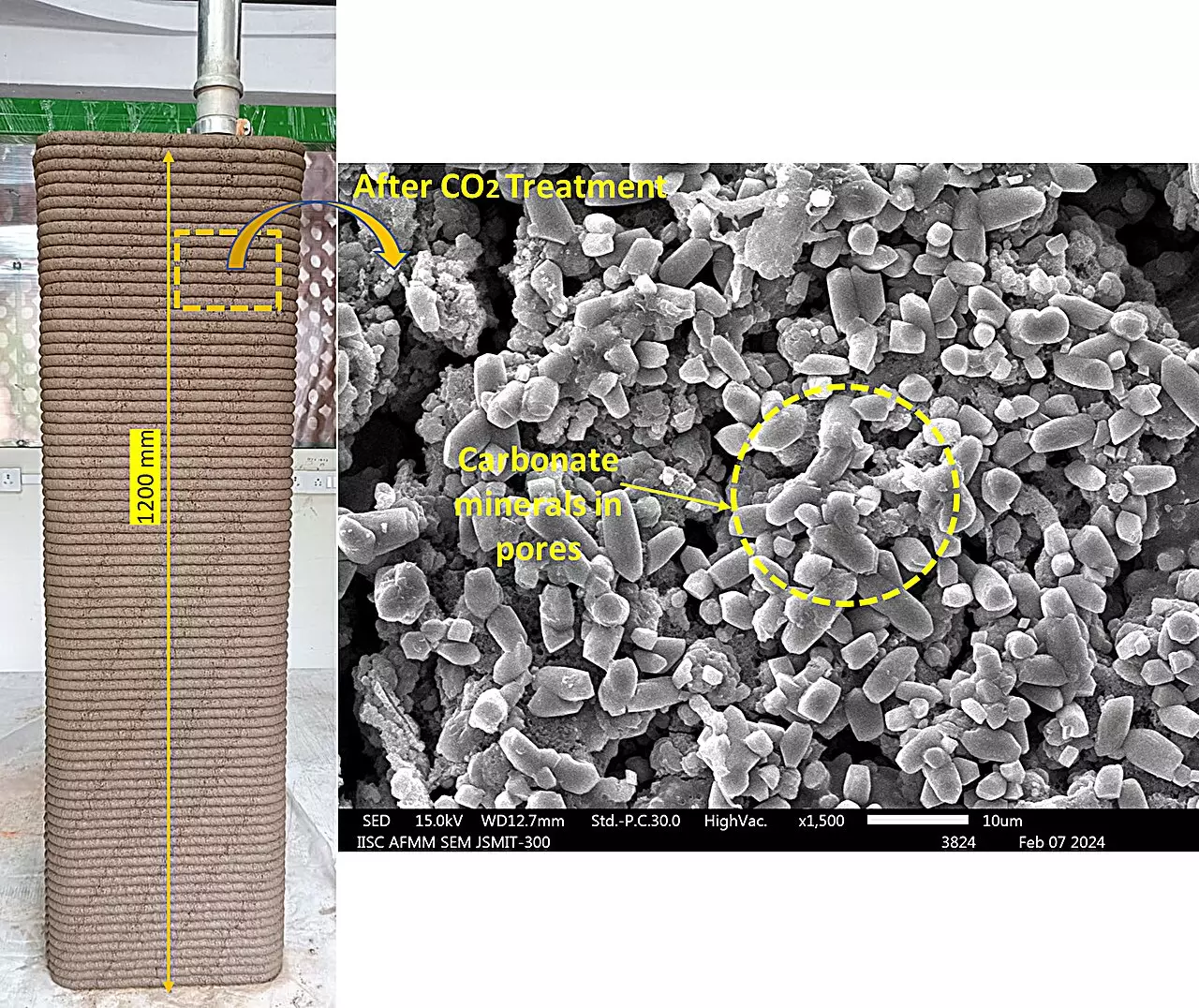

In a notable study published in Construction and Building Materials, researchers demonstrated the efficacy of replacing natural sand with carbon dioxide-treated C&D waste in mortar. By subjecting the material to curing in a controlled, CO2-rich environment, they observed a significant enhancement in compressive strength by 20-22%. Furthermore, injecting carbon dioxide gas into clayey soil resulted in improved stabilization of clay, reduced surface area, and enhanced bulk engineering performance, as reported in Developments in the Built Environment.

In a recent study published in Science of The Total Environment, the team investigated the sequestration of carbon dioxide in excavated soil to develop cement-lime-soil materials. These materials, when used to replace fine aggregates in mortar, exhibited a remarkable improvement in compressive strength due to the formation of calcium carbonates. Exposure to carbon dioxide also accelerated early-age strength development and reduced curing time, thereby enhancing the suitability of the materials for construction applications.

The development of 3D-printable materials utilizing excavated soil stabilized with binders like Portland cement, blast furnace slag, and fly ash offers a promising avenue for sustainable construction. These materials, which exhibit superior extrusion and buildability compared to conventional cement-sand mortars, have the potential to reduce the reliance on cement and natural sand by significant margins. The innovative approach not only addresses environmental concerns but also enhances the overall efficiency and sustainability of construction practices.

Moving forward, the research team plans to delve deeper into the effects of industrial and simulated flue gas on the properties of newly formulated materials. By exploring how gases other than carbon dioxide impact the materials’ carbon-capturing potential and engineering properties, they aim to broaden the scope of their sustainable construction innovations. Furthermore, collaborations with major construction companies are underway to implement these findings in manufacturing plants and contribute to a greener, more sustainable construction industry.

The pioneering efforts of researchers at CST underscore the transformative potential of sustainable material development in the construction sector. By embracing innovative solutions and collaborative partnerships, the industry can mitigate environmental challenges, reduce carbon footprint, and pave the way for a more sustainable future.

Leave a Reply