Detecting defects in additively manufactured components is a critical task in the manufacturing industry. Additive manufacturing, also known as 3D printing, presents a unique challenge when it comes to identifying defects. This is due to the complex three-dimensional shapes and internal features of components that can be difficult to observe with the naked eye. As a result, traditional methods of defect detection may not be sufficient in this context.

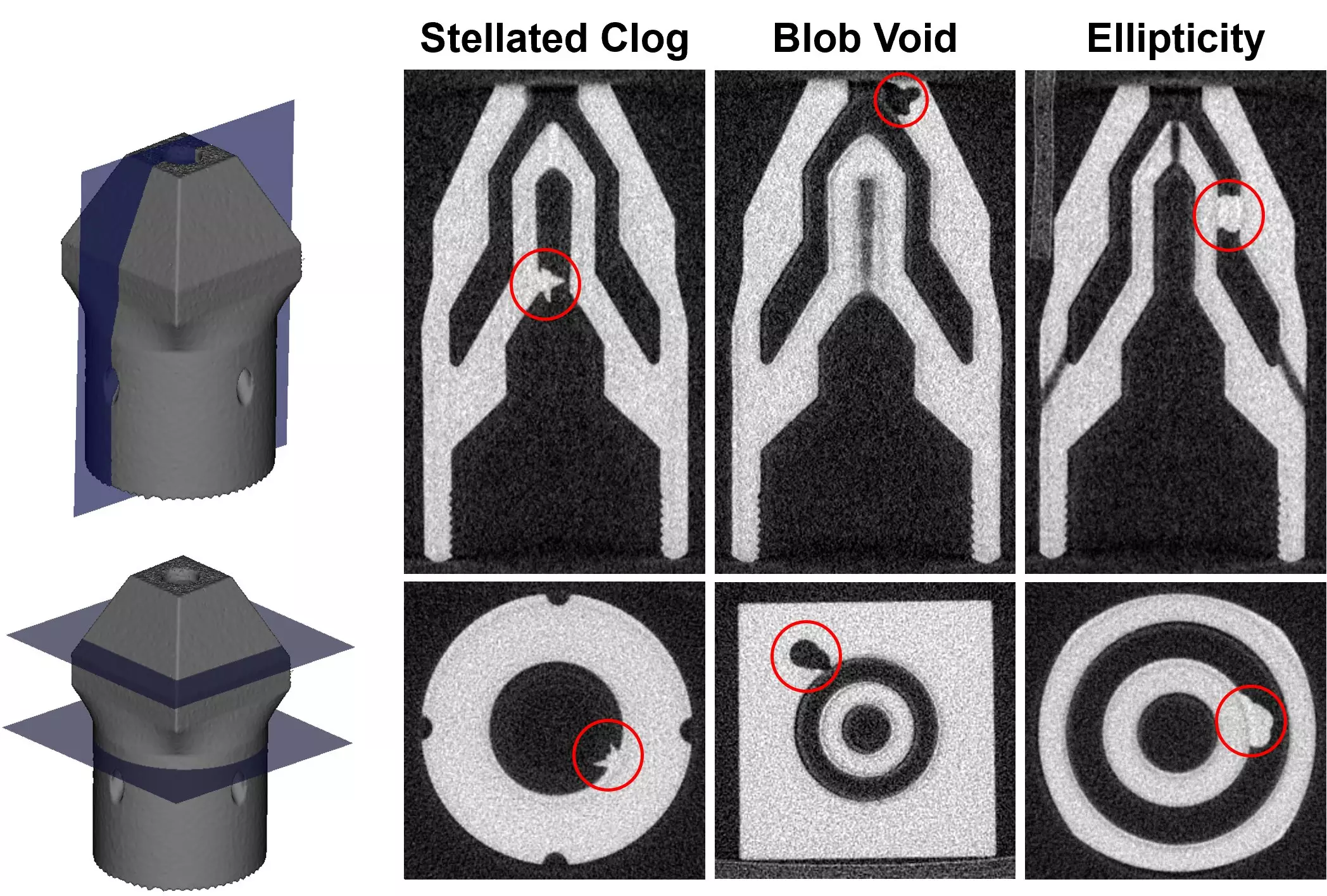

Researchers at the University of Illinois Urbana-Champaign have developed a groundbreaking method for detecting defects in additively manufactured components using deep machine learning. By utilizing computer simulations to generate synthetic defects with varying sizes, shapes, and locations, the deep learning model was able to train on a wide range of possible defects. This approach allowed the algorithm to accurately differentiate between defective and defect-free components.

The algorithm developed by the researchers was put to the test on physical parts, some of which contained defects that had not been previously seen by the deep learning model. The results were impressive, with the algorithm successfully identifying hundreds of defects in real physical parts. This technology addresses a significant challenge in additive manufacturing, providing a fast and accurate method for defect detection that was previously unattainable.

The research published in the Journal of Intelligent Manufacturing utilized X-ray computed tomography to inspect the interior of 3D components. This technology is crucial for detecting defects that are hidden from view, especially in components with intricate internal features. The combination of deep learning and X-ray computed tomography proved to be highly effective in identifying hidden defects in additively manufactured parts.

The development of innovative technologies such as deep machine learning and X-ray computed tomography has revolutionized the process of defect detection in additively manufactured components. These advancements not only improve the quality of manufactured products but also streamline the manufacturing process by enabling quick and accurate defect identification. The research conducted by the team at the University of Illinois Urbana-Champaign marks a significant milestone in the field of additive manufacturing and sets a new standard for defect detection in the industry.

Leave a Reply