Materials are at the heart of technological advancements, particularly in fields that demand peak performance under extreme conditions, such as nuclear energy and military systems. The integrity of these materials is often tested under severe conditions including high pressure, temperature fluctuations, and corrosive environments. Understanding how materials behave on a lattice level in such scenarios is crucial for the creation of future materials that meet the demands for resilience, affordability, lightweight properties, and sustainability.

Researchers at Lawrence Livermore National Laboratory (LLNL) have recently published groundbreaking findings regarding the behavior of zirconium under high pressure. By compressing single crystal samples of this metal, scientists have uncovered a complex deformation pattern that defies previous expectations. The results of this research have been documented in prominent journals, specifically Physical Review Letters and Physical Review B.

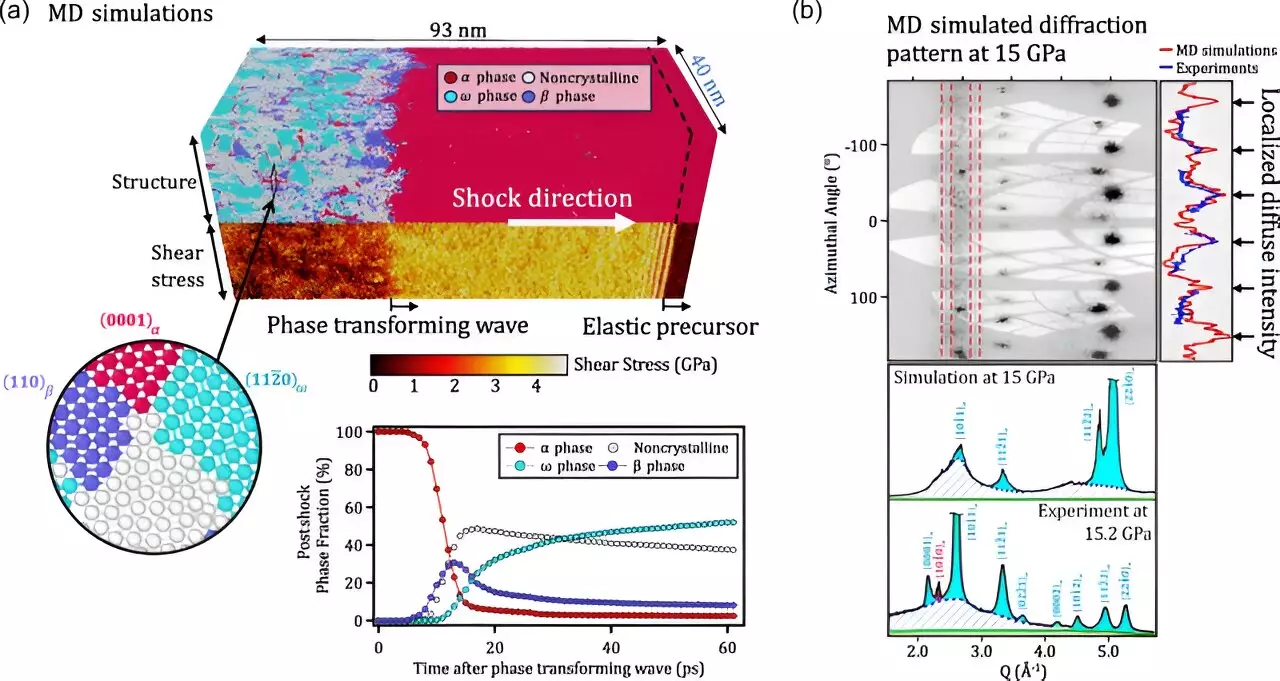

The study highlights how materials subjected to extreme stress relieve shear strains through a variety of mechanisms. These methods include but are not limited to dislocation slip, crystallographic twinning, shear-induced amorphization, and phase transformations. As LLNL scientist Saransh Soderlind notes, a comprehensive understanding of these nuances is fundamental for forecasting material performance in real-world applications.

When metals are subjected to compression, they undergo plastic deformation, which is essentially a permanent alteration of their shape. This process is primarily driven by dislocations—defects that enable atoms to shift along specific planes in defined crystallographic directions. In the case of zirconium, researchers discovered that its behavior is further complicated by its transformation to a different crystal structure under increasing pressure. Soderlind emphasizes that tracking these crystallographic details can lead to more accurate predictive models that enhance our understanding of material mechanics at extreme levels of stress.

The research utilized advanced experimental methods, employing femtosecond in-situ X-ray diffraction. This technique enabled scientists to monitor the behavior of zirconium crystals as they were compressed over exceptionally short timescales. The researchers made several astonishing discoveries, including the revelation of atomic disorder—a phenomenon that had never been recorded in an elemental metal—and the identification of multiple pathways for crystal structure transformations. The occurrence of these phenomena was conspicuously absent in studies of polycrystalline zirconium, marking a significant advancement in material science.

Moreover, the team’s multi-million atom molecular dynamics simulations using a machine-learned potential have validated their experimental findings, resulting in a richer understanding of atomic behavior under extreme conditions. As LLNL scientist Raymond Smith points out, the observations stemming from this research present an intricate portrayal of metallic deformation, suggesting that these complexities may be prevalent in other materials subjected to similar pressures.

Zirconium alloys play an integral role in the nuclear sector as fuel rod cladding, praised for their strength and minimal neutron absorption capability. Their utility extends into numerous industries that contend with harsh chemical environments. The findings from LLNL not only deepen our understanding of zirconium’s behavior but also pave the way for the development of next-generation materials. As scientists continue to unravel these complexities, the implications for both current and future technologies remain expansive and promising.

Leave a Reply